The Electronics Division of Marki Group Ltd is looking back over 40 years of history in the field of electronic assembly through its predecessors. Our main goal is to produce quality products within shortest delivery term, which will ensure our long-term competitiveness in the Western European market.

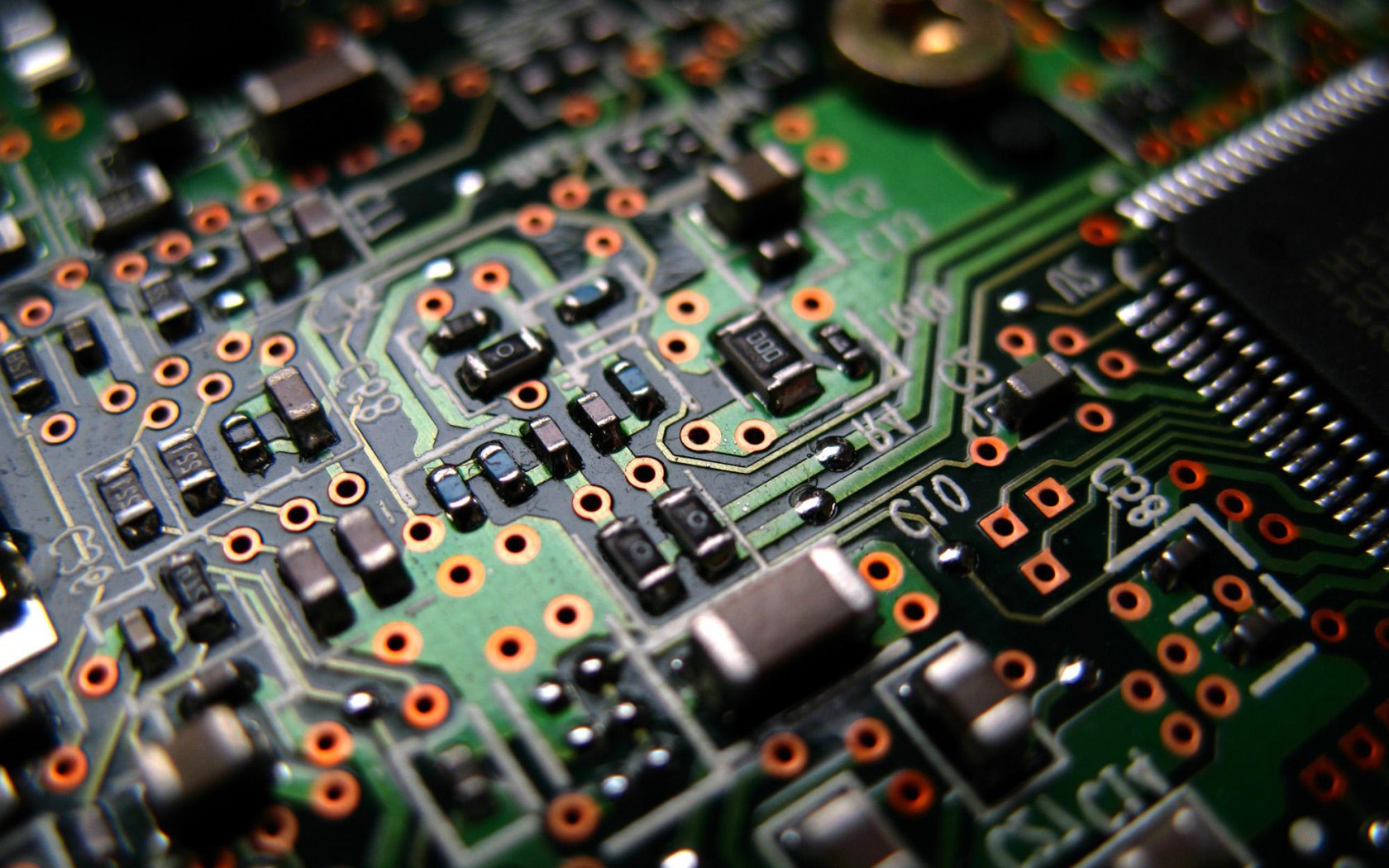

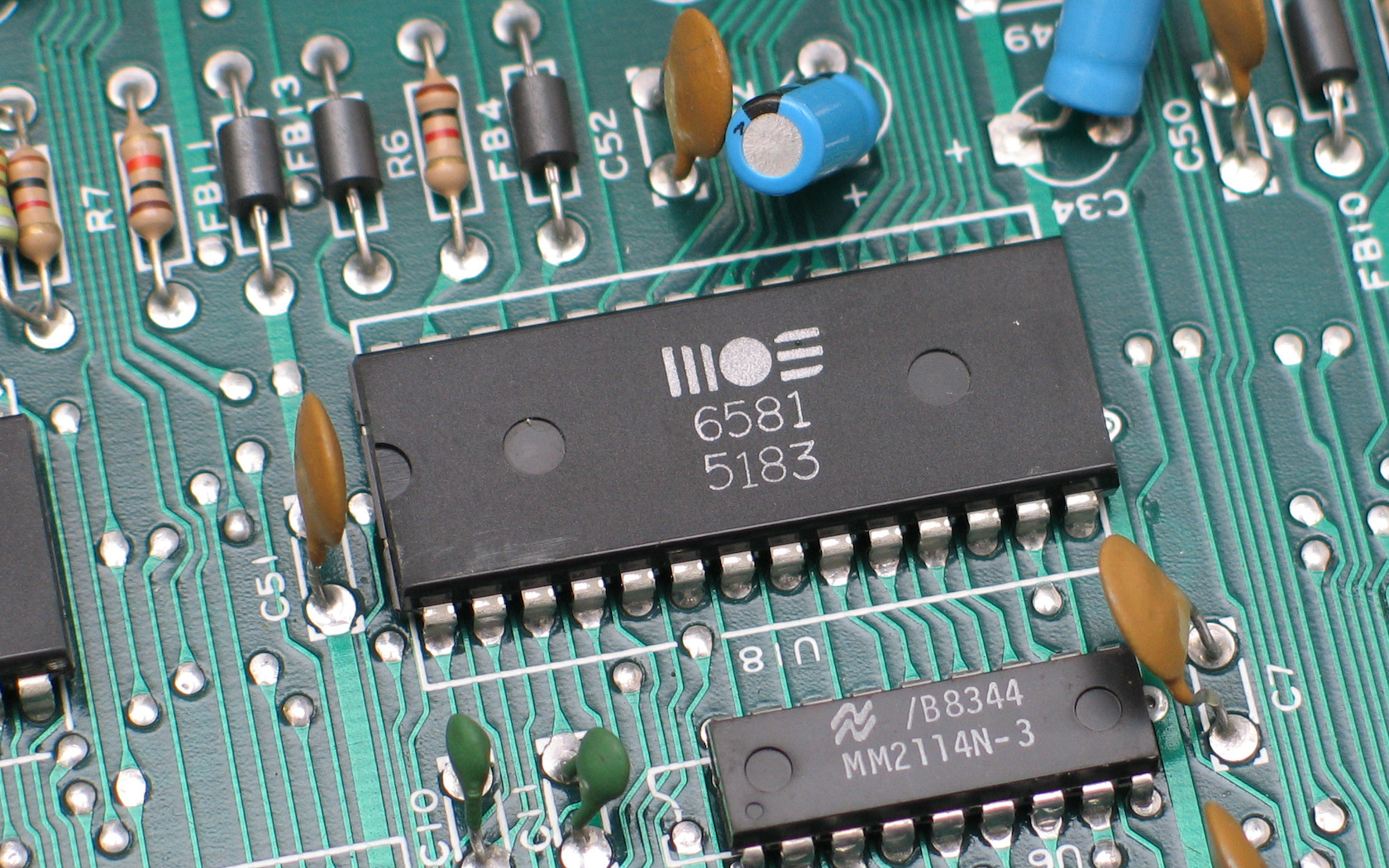

Our main profile is the production of small and medium series (50-10,000 pcs / series) assembled PCB’s with the most modern technology, with decades of experience, in ESD-antistatic environment, with full-scale material procurement or in wage work.

Our commitment to quality proves that our company operates in accordance with the ISO9001: 2015 Quality Management System guidelines.

Preparation of various part types (cutting, bending) using HELLER, EBSOMAT and ITECO machines. Upon request, we develop and manufacture special machines for the production.

Wave soldering is made with lead-free ATF 33 soldering machine using low-dry content "No Clean Flux"

We undertake the resin potting of the PCB’s with Bartec machine and we also undertake the protective painting of the PCB’s.

According to your order, we can carry out ICT, FUT and Final Control tests.

In all areas, we are committed to excellence, all our decisions and activities show the sincere effort to make our customers, owners and employees of Marki Group satisfied and we are continuously increasing this satisfaction year after year.

One of the key features of this is the acquisition of ISO 9001: 2015 Certification, continuous operation and development of the implemented quality management system.

With our flexibility and customer focus, we are a major manufacturing base for designer and developer companies in the German speaking countries, whether in the automotive, home electronics or medical electronics sectors.

Marki Group Ltd operates an ISO 9001: 2015 quality management system certified by Bureau Veritas Certification.

Certificate number: HU004216.

Printing of special barcode and matrix labels to uniquely identify your products.

According to your order, we carry our AOI, ICT, FUT, and Final Control tests and 100% visual inspection.

Storing according to FIFO principle. Component management according to JEDEC-STD-033, JEDEC-STD-020.

Production in ESD environment according to IPC 610 Class II or III. as per customer requirements. Assembly of cables and wiring harnesses according to IPC 620.

Our company adheres to the European Union guidelines on data management (GDPR). Accordingly, it records and manages the personal data of the partners in accordance with the provisions of the GDPR.

The Data Management Policy was prepared by Marki Group Ltd. on the basis of and in accordance with Regulation No 2016/679 of the European Parliament and Council ("General Data Protection Regulation").

| Managing Director: | Mr Imre Asztalos |

| Tel: | +3620-399-1870 |

| E-mail: | imre.asztalos@markikft.hu |

| Sales: | Mr Szabolcs Kelemen |

| Tel: | +3620-220-9383 |

| E-mail: | sales@markikft.hu |

| Address: | 3300 Eger, Gyetvai József utca 13. |

| Web: | www.markikft.hu |